ZEROS PRODUCTS

M3

M3

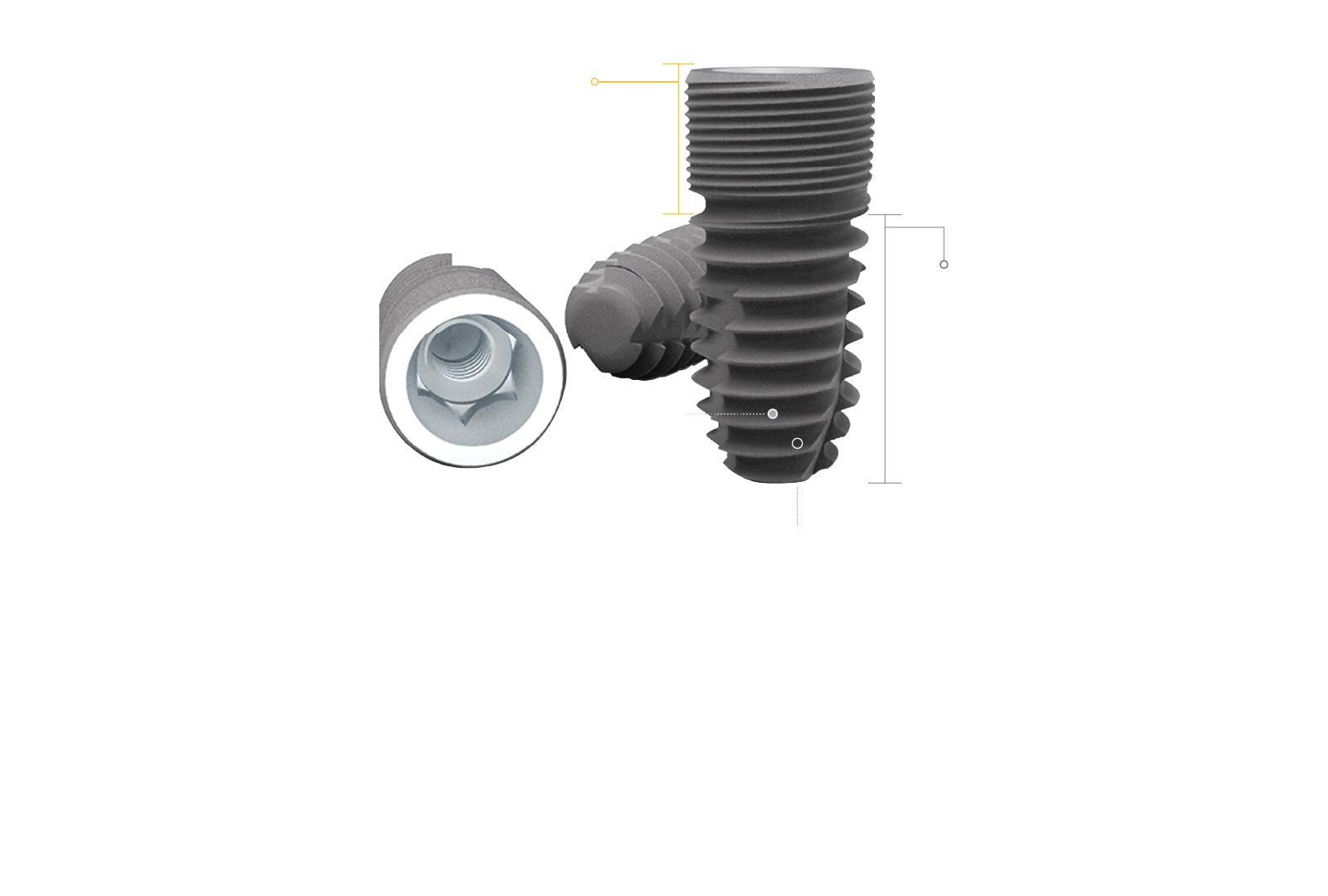

FIXTURE DESIGN

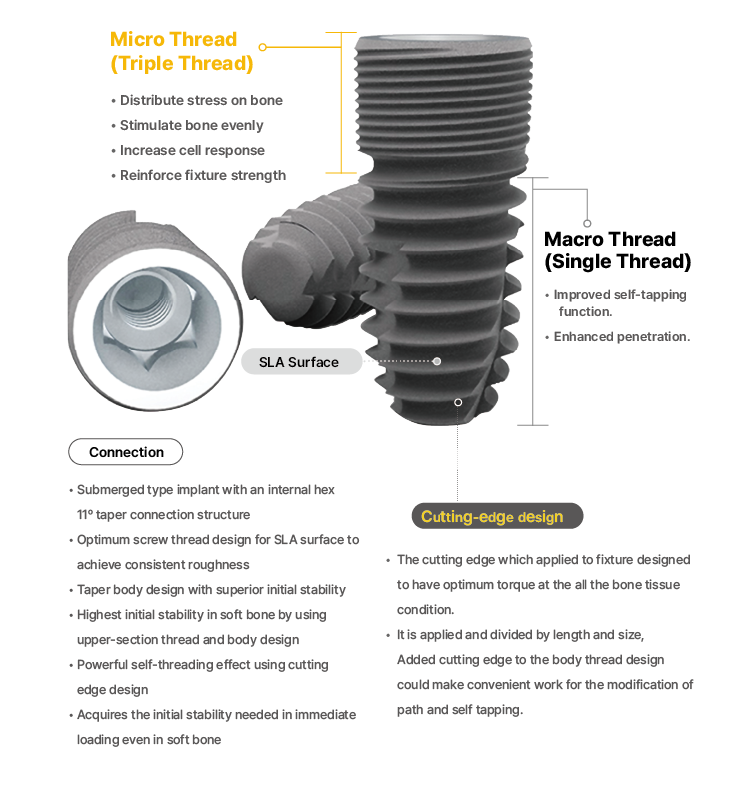

Micro Thread

(Triple Thread)

• Distribute stress on bone

• Stimulate bone evenly

• Increase cell response

• Reinforce fixture strength

Connection

• Submerged type implant with an internal hex

11º taper connection structure

• Optimum screw thread design for SLA surface

to achieve consistent roughness

• Taper body design with superior initial

stability

• Highest initial stability in soft bone by using

upper-section thread and body design

• Powerful self-threading effect using cutting

edge design

• Acquires the initial stability needed in

immediate loading even in soft bone

Cutting Edge Design

• The cutting edge which applied to fixture designed

to have optimum torque at the all the bone tissue

condition.

• It is applied and divided by length and size,

Added cutting edge to the body thread design

could make convenient work for the modification of

path and self tapping.

SLA Surface

Macro Thread

(Single Thread)

• Improved self-tapping

function.

• Enhanced penetration.

M3

FIXTURE DESIGN

ZEROS PRODUCTS

M3

M3

FIXTURE DESIGN

x1000

x3000

S.L.A SURFACE

• Surface of fixture are excellent in morphology and roughness.

Increased 50% of the surface area than RBM

• The S.L.A Surface and the entire taper shape of M2, M3 fixture could

get enough initial fix

x1000

x3000

S.L.A SURFACE

• Surface of fixture are excellent in morphology and reughness.

Increased 50% of the surface area than RBM

• The S.L.A Surface and the entire taper shape of M2, M3 fixture could

get enough initial fix

• Surface of fixture are excellent in

morphology and reughness.

Increased 50% of the surface area

than RBM

• The S.L.A Surface and the

entire taper

shape of M2, M3 fixture could

get enough initial fix

M3

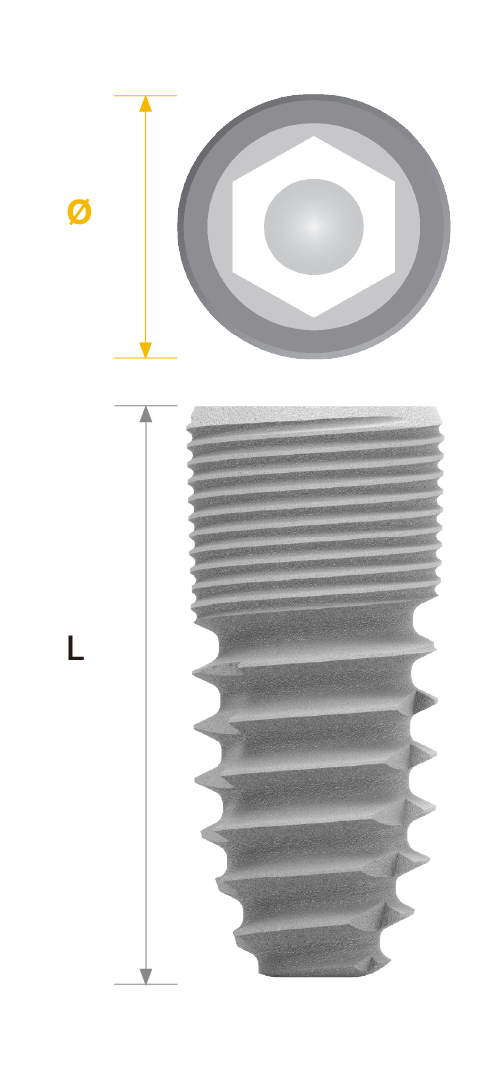

FIXTURE

Micro Thread

(Triple Thread)

• Distribute stress on bone

• Stimulate bone evenly

• Increase cell response

• Reinforce fixture strength

Macro Thread

(Single Thread)

• Improved self-tapping function

• Enhanced penetration

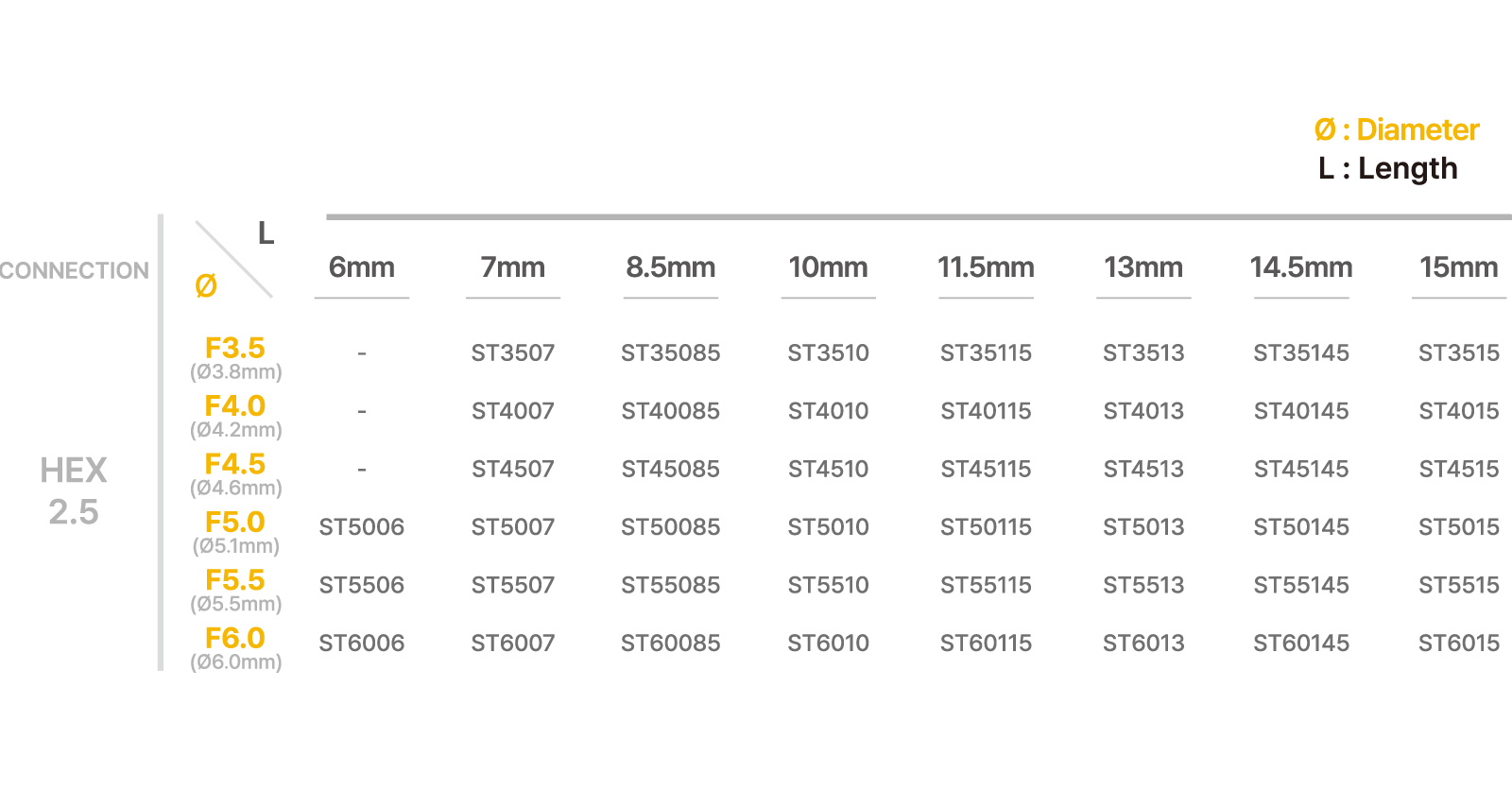

Surface Treatment : SLA

Internal Hex : 2.5mm

Morse Taper : 11°

Female Screw : M2.0

You cannot copy content of this page